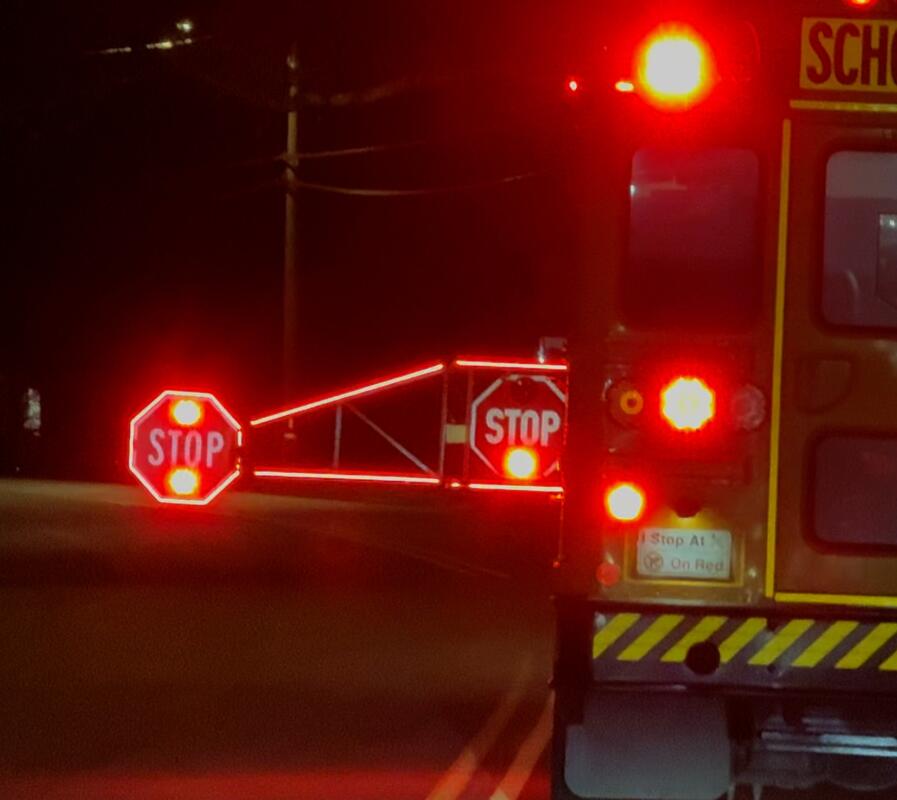

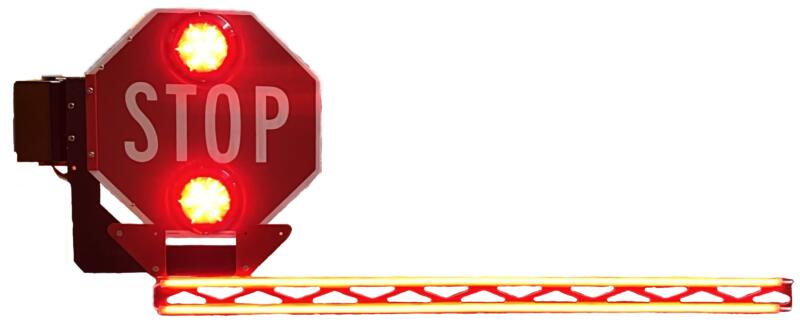

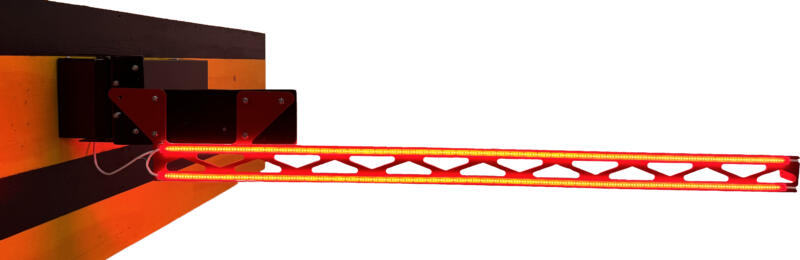

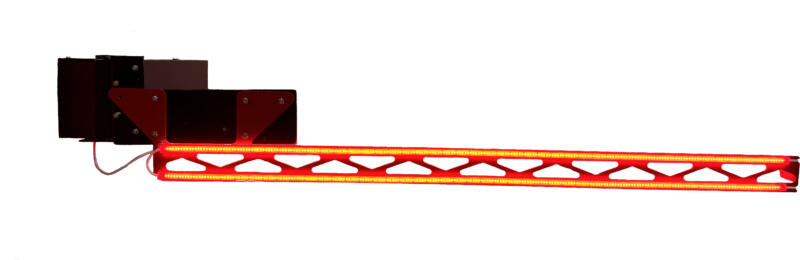

The SureStop: Standard Arm Bus-Gates Adapter is a bracket that allows the attachment of a Bus-Gate to the SureStop: Standard Arm. The SureStop system is designed to carry the additional load of the Bus-Gate Unit when attached with the bracket. The bracket disburses the weight and stress of the Bus-Gate to the unit itself as opposed to the sign.

It is fully compatible with units 180110 and 180112 which are sold separately.

Bus-Gate units are sold separately.

SureStop: Standard Arm – Bus-Gates Adapter

The SureStop: Standard Arm is an FMVSS school bus pedestrian stop arm. It is powered by an electric or pneumatic actuator.

The patent pending mechanism is designed to meet the harsh environmental conditions in which school buses operate.

A standard stop sign meeting FMVSS 131 Color and Reflectivity standards is mounted

to the SureStop unit. The sign is coated with 3M Diamond Grade coating for superior retro reflectivity. It has two LED flashing lights on each side which meet FMVSS 131 brightness standards. Lights are independently plugged into the wiring harness. Meaning any light can be replaced individually. All 9 bright LEDS are in sealed housing and US FMVSS 108 vehicle lighting compliant.

The SureStop Standard Arm is motorized by an electric actuator or pneumatic cylinder that exerts 100 lbs. pressure to open the arm, allowing them to operate in the worst environmental conditions.

Linear Actuator

- This is a 100# thrust unit, with an IP66M rating operating at a temperature range of -40 F to 130 F providing consistent operations of the Sure Stop Arm. This has a 100# static load for keeping the arm against the side of the bus. The electric actuators require 12 v power from the school bus.

- The electronic control system is motorized in the sealed box. Electrical wiring is all U.V. protected cabling.

- The electrical control unit controls the flash, and strobe of the lights, as well as the linear actuator. This requires a 15-amp supply line fuse from the fuse box, and to be connected to the control wire for the existing Stop Arm lights. The unit uses an average of 3-amps constant with 6-amp peak.

FMVSS Citations

- SureStop Arms meet all Federal Motor Vehicle Standards for School Bus Stop Arms – FMVSS §571.131. The specifications are listed with reference to the sections in the Federal standards.

Stop Sign Characteristics

- Stop sign is octagonal – 450 mm in diameter (§5.1)

- Stop sign is red (§6.2.1) on both sides – excluding letters and borders (§5.2)

- Stop sign has 12 mm white boarder (§5.2.1)

- Mounting brackets do not obscure more than 15 percent of border (§5.2.3)

- The words “STOP” is displayed in upper case letters and are 150 mm in height. Stroke width is at least 20 mm (§5.2.2)

- Stop sign is reflectorized (§6.2) with Type III material ($5.3.1) that meets the Minimum Specific Intensity Per Unit Area ($571.135)

- Brackets and Mounts account for less than 7.5 percent of the total surface area of either side of the stop arm (S5.3.1.2)

- The stop sign is equipped with two red lamps on either side of the sign. The lamps are centered on the vertical centerline at the top and bottom of the sign. (S5.3.2)

Stop Arm Mounting

- The stop arm is mounted perpendicular to the side of the bus. The top edge of the sign is mounted parallel to the windows. The vertical centerline of the sign is greater than 9 inches from the side of the bus. (§5.4.1 a, b, c)

Stop Arm Controls

- Stop arm is activated with the “reds” switch on the console (§5.5)

Stop Arm Lamps

- DOT/SAE:J1395, J1398, J585e Rated

-

- Flash rate shall have a current “on” time of 30 to 75 percent of the total flash cycle. The total current “on” time for the two terminals is between 90 and 110 percent of the total flash cycle. (§6.2.1)

Stop Arm Durability

- The stop arm is held secure to the bus with 4 #12 screws to resist vibration. (§6.2.3)

- All parts are coated or made of weather resistant materials to prevent corrosion.

- The electronics meet IP66 to resist moisture and dust. (§6.2.3)

- Electrical wiring and plastics are coated with U.V. protected cabling. (§6.2.3)

- Stop sign is made of .08 aluminum and does not warp. (§6.2.3)

- Control box frame parts are powder-coated steel and do not warp (§6.2.3)

Warranty

- SureStop Arms have a 5-year parts warranty.

Durability

- The product withstands the heavy vibration of washboard roads, extreme temperatures, and high winds. Lab testing has performed over 10 years of operations, 500,000 extensions and retractions, with electric actuator under respective load.