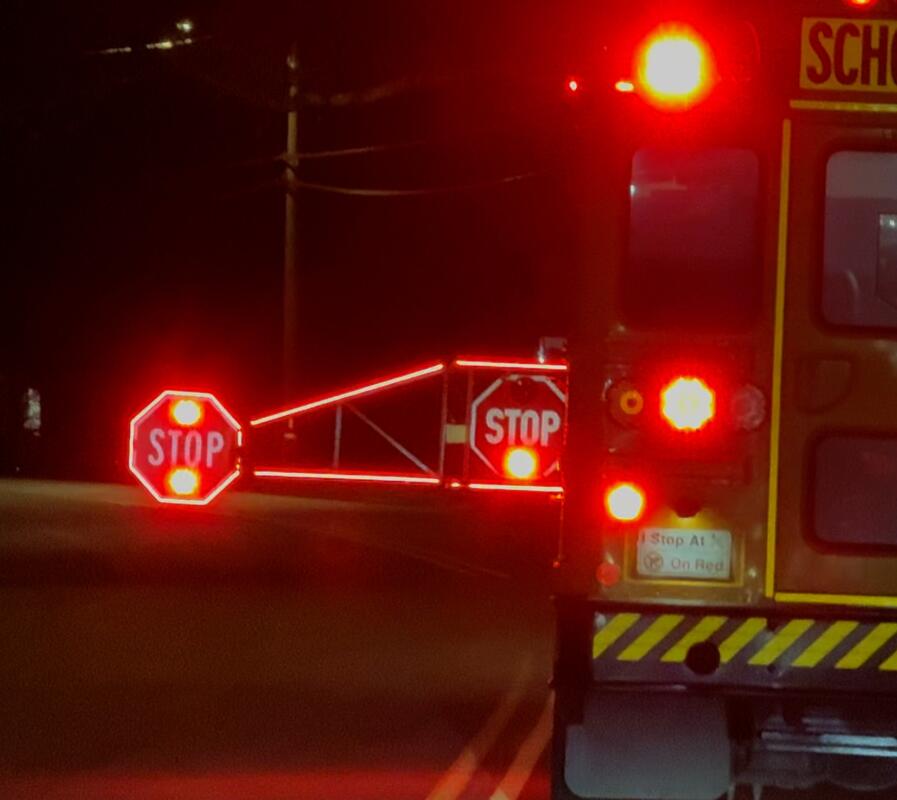

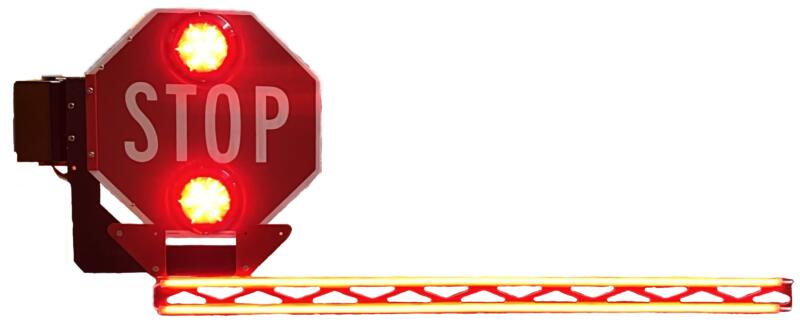

The Driver Select unit for Bus-Gate is an electric actuator or pneumatic cylinder powered unit that mounts underneath a standard stop arm and extends a Bus-Gate in conjunction with the stop arm. The school bus driver is equipped with a switch that allows them to disable the arm if there is a vehicle or other object obstructing the extension.

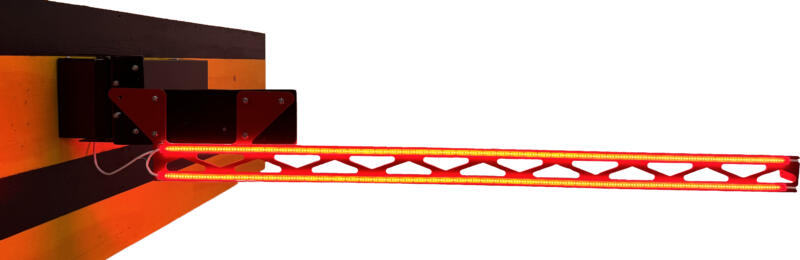

The patent pending mechanism is designed to meet the harsh environmental conditions in which school buses operate.

The Driver Select unit is motivated by an electric actuator or pneumatic cylinder that exerts 100 lbs. pressure to open the unit, allowing them to operate in the worst environmental conditions.

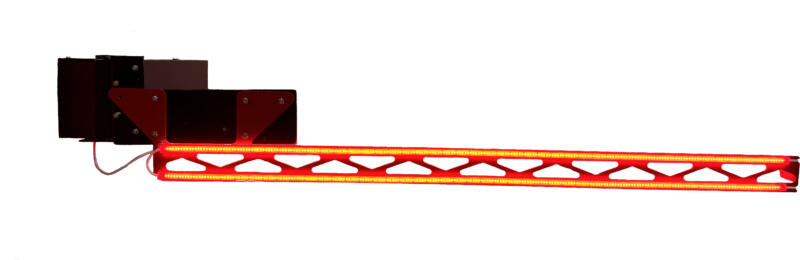

Linear Actuator – This is a 100# thrust unit, with an IP66M rating operating at a temperature range of -40 F to 130 F providing consistent operations of the unit. This has a 100# static load for keeping the Bus-Gate against the side of the bus. The electric actuators require 12v power from the school bus.

The electronic control system is mounted in the sealed box. Electrical wiring is all U.V. protected cabling.

The electrical control unit controls the flash, and strobe of the lights, as well as the linear actuator. This requires a 15-amp supply line fuse from the fuse box, and to be connected to the control wire for the existing Stop Arm lights. The unit uses an average of 3-amps constant with 6-amp peak.

Mounting

- The Driver Select unit is mounted perpendicular to the side of the bus.

Controls

- Driver Select is activated with the “reds” switch on the console.

- A second switch allows the driver to disable the unit.

SureStop Durability

- The unit is held secure to the bus with 4 #14 screws to resist vibration.

- All parts are coated or made of weather resistant materials to prevent corrosion.

- The electronics meet IP66 to resist moisture and dust.

- Electrical wiring and plastics are coated with U.V. protected cabling.

- Control box frame parts are powder-coated steel and do not warp.

Warranty

- Driver Select units have a 2-year parts warranty.

Durability

- The product withstands the heavy vibration of washboard roads, extreme temperatures, and high winds. Lab testing has performed over 10 years of operations, 500,000 extensions and retractions, with electric actuator or pneumatic cylinder under respective load.